Types/Variations: There are different kinds of brakes. Some uses frictional blocks that are simply pressed against the interior surface of the hub of the rotating wheel while some uses discs.

Brake assemblies commonly used on aircraft are the single-disk, dual-disk, multiple-disk, segmented rotor, or expander tube types. The single- and dual-disk types are more commonly used on small aircraft; the multiple-disk type is normally used on medium-sized aircraft; and the segmented rotor and expander tube types are commonly found on heavier aircraft.

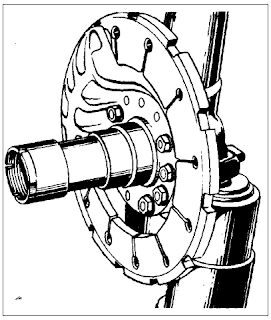

Single-Disk Brakes: With the single-disk brake, braking is accomplished by applying friction to both sides of a rotating disk which is keyed to the landing gear wheel. There are several variations of the single disk brake; however, all operate on the same principle and differ mainly in the number of cylinders and the type of brake housing. Brake housings may be either the one-piece or divided type. Figure 5.1 shows a single-disk brake installed on an aircraft, with the wheel removed. The brake housing is attached to the landing gear axle flange by mounting bolts.

Figure 5.2 shows an exploded view of a typical single-disk brake assembly. This brake assembly has a three-cylinder, one-piece housing. Each cylinder in the housing contains a piston, a return spring, and an automatic adjusting pin.

Hydraulic pressure from the brake control unit enters the brake cylinders and forces the pistons and their pucks against the rotating disk. The rotating disk is keyed to the landing gear wheel so that it is free to move laterally within the brake cavity of the wheel. Thus, the rotating disk is forced into contact with the inboard pucks mounted in the housing. The lateral movement of the rotating disk ensures equal braking action on both sides of the disk.

When brake pressure is released, the return springs force the pistons back to provide a preset clearance between the pucks and the disk. The self. adjusting feature of the brake will maintain the desired puck-to-disk clearance, regardless of lining wear.

Brake assemblies commonly used on aircraft are the single-disk, dual-disk, multiple-disk, segmented rotor, or expander tube types. The single- and dual-disk types are more commonly used on small aircraft; the multiple-disk type is normally used on medium-sized aircraft; and the segmented rotor and expander tube types are commonly found on heavier aircraft.

Single-Disk Brakes: With the single-disk brake, braking is accomplished by applying friction to both sides of a rotating disk which is keyed to the landing gear wheel. There are several variations of the single disk brake; however, all operate on the same principle and differ mainly in the number of cylinders and the type of brake housing. Brake housings may be either the one-piece or divided type. Figure 5.1 shows a single-disk brake installed on an aircraft, with the wheel removed. The brake housing is attached to the landing gear axle flange by mounting bolts.

Figure 5.2 shows an exploded view of a typical single-disk brake assembly. This brake assembly has a three-cylinder, one-piece housing. Each cylinder in the housing contains a piston, a return spring, and an automatic adjusting pin.

| ||

| Figure 5.1: Typical single-disk brake installation |

There are six brake linings, three on the inboard side of the rotating disk and three on the outboard side of the rotating disk These brake linings are often referred to as "pucks." The outboard lining pucks are attached to the three pistons and move in and out of the three cylinders when the brakes are operated. The inboard lining pucks are mounted in recesses in the brake housing and are therefore stationary.

Hydraulic pressure from the brake control unit enters the brake cylinders and forces the pistons and their pucks against the rotating disk. The rotating disk is keyed to the landing gear wheel so that it is free to move laterally within the brake cavity of the wheel. Thus, the rotating disk is forced into contact with the inboard pucks mounted in the housing. The lateral movement of the rotating disk ensures equal braking action on both sides of the disk.

When brake pressure is released, the return springs force the pistons back to provide a preset clearance between the pucks and the disk. The self. adjusting feature of the brake will maintain the desired puck-to-disk clearance, regardless of lining wear.

No comments:

Post a Comment